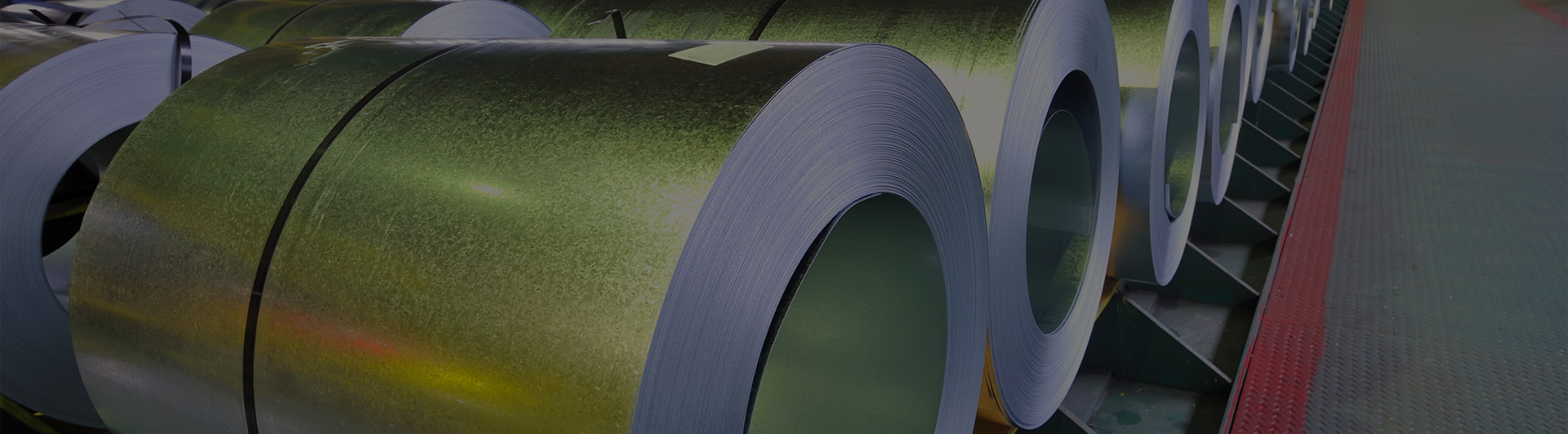

HOT ROLLED STRIP COIL PROCESS(HRC)

COLD ROLLED STRIP COIL PROCESS(CRC)

Steel strip production line

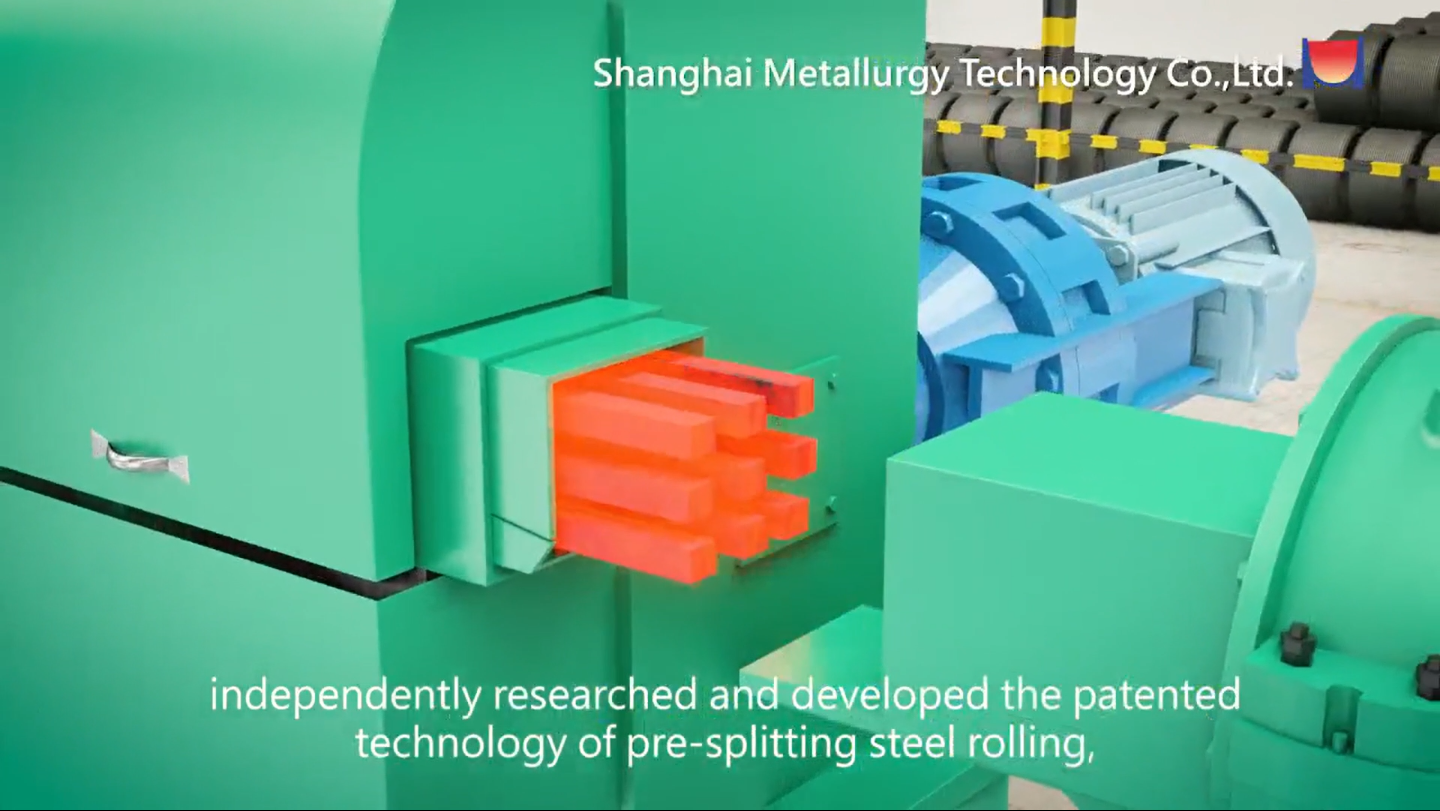

SME has delivered a number of traditional strip production lines for customers, including cold-rolled strip production lines and hot-rolled strip production lines, but the process of traditional strip production is more complicated than other rolled steel production lines, and the investment cost is higher. The patented technology of Pre-Slitting self-developed by SME can be perfectly applied to the strip steel production line, giving play to the performance beyond the traditional production line.Regardless of the configuration - semi-continuous or continuous - or other particular technical solutions, The application of Pre-Slitting technology has greatly reduced the equipment of traditional production lines and fundamentally reduced investment costs.

SME proposes a “tailor-made” layout, including all the state-of-the-art technology packages that ensure improved product quality. At the same time, considerable attention is paid to implementing solutions that save on operating and maintenance costs, thereby additionally increasing the customer’s competitiveness.

With thin thickness, narrow width and long length. Its width is generally 20mm-200mm. It is supplied in rolls, and its specifications are expressed as thickness × width. According to the quality of the steel, it is divided into high-quality and ordinary strip; according to the rolling method, it is divided into hot-rolled and cold-rolled, which are called hot-rolled strip and cold-rolled strip respectively. The thickness of hot-rolled ordinary strip is 2 mm-6 mm, and the thickness of cold-rolled strip is generally 0.05 mm-3.60 mm. Strip steel can be made of ordinary carbon steel, carbon structure steel, spring steel, tool steel, stainless steel and other steel grades. Widely used in the manufacture of welded pipes, clamps, gaskets, spring blades, saw blades, blades, etc.

1.The production process of cold-rolled strip steel is generally: pickling → rolling → process lubrication → annealing → leveling → shearing → packaging.

2.Cold-rolled strip steel coil(CRC) process: descaling-pickling(acid washing) - cold rolling - annealing furnace - rolling size synchronous lubrication - anti-rust oil - leveling and sizing - polishing - packaging

3.Hot rolled strip coil(HRC) process: heating furnace - dephosphorization machine - rough rolling mill - dephosphorization machine - finishing mill - surface quality tester - layer cooling - coiling machine - baler - spray number Machine - roll warehouse slab

Strip steel is generally supplied in coils, which have the advantages of high dimensional accuracy, good surface quality, easy processing, and material saving.

All this means that our patented technology of Pre-Slitting is designed to fulfil not only today’s market demands but also to meet new challenges, in terms of strip quality, product versatility, cost-effectiveness and production performances.

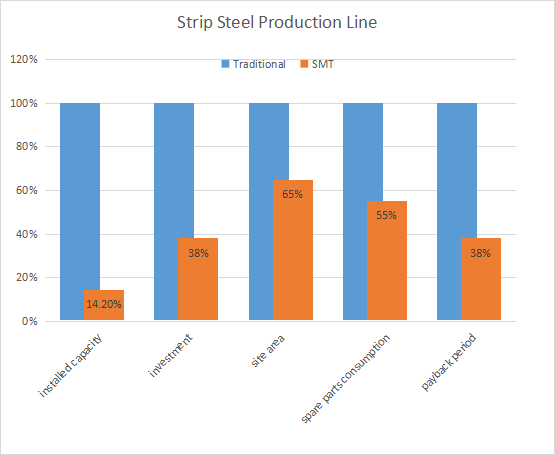

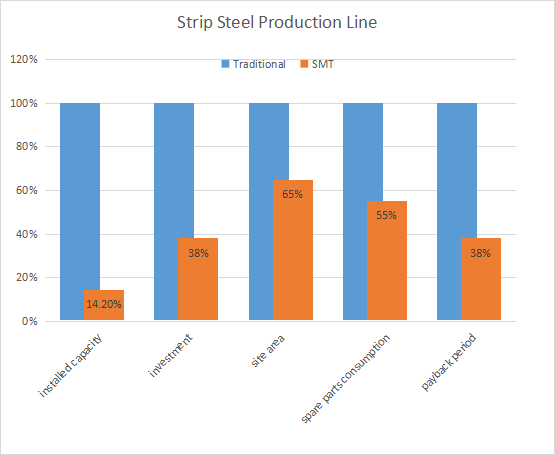

Investment comparison between SME with traditional bar production line as follow

Remarks: The comparative data is based on the same production capacity