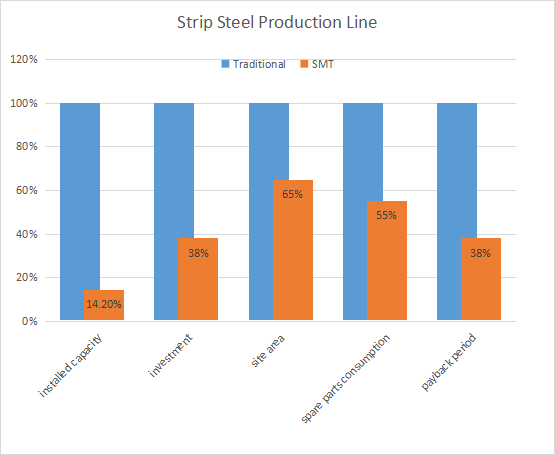

SMT has delivered a number of traditional strip production lines for customers, including cold-rolled strip production lines and hot-rolled strip production lines, but the process of traditional strip production is more complicated than other rolled steel production lines, and the investment cost is higher. The patented technology of Pre-Slitting self-developed by SMT can be perfectly applied to the strip steel production line, giving play to the performance beyond the traditional production line.Regardless of the configuration - semi-continuous or continuous - or other particular technical solutions, The application of Pre-Slitting technology has greatly reduced the equipment of traditional production lines and fundamentally reduced investment costs.

SMT proposes a “tailor-made” layout, including all the state-of-the-art technology packages that ensure improved product quality. At the same time, considerable attention is paid to implementing solutions that save on operating and maintenance costs, thereby additionally increasing the customer’s competitiveness.

All this means that our patented technology of Pre-Slitting is designed to fulfil not only today’s market demands but also to meet new challenges, in terms of strip quality, product versatility, cost-effectiveness and production performances.

Investment comparison between SMT with traditional bar production line as follow

Remarks: The comparative data is based on the same production capacity

SMT insist on creating value for customers with...

Apr. 16 , 2021

We adhere to the people-oriented development conc...

Apr. 06 , 2021Shanghai Metallurgy Technology Co., Ltd.

E-mail: Metallurgy@smteel.com

Skype: +86 189 1827 7118

Tel.: +86 189 1827 7118

Add.: Kangqiao, Pudong new district, Shanghai, China.