Structural Steel

section steel, H beam, U channeal, I beam, Rail and specific shapes

Structural steel is a category of steel used for making construction materials in a variety of shapes, including steel pipe, angle steel and H beam steel and so on. Many section steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

Most structural steel shapes, such as I-beams, have high second moments of area, which means they are very stiff in respect to their cross-sectional area and thus can support a high load without excessive sagging.

Steel profile are used to build efficient, reliable and cost-efficient envelopes of mostly commercial buildings. They have evolved from the single skin metal cladding often associated with agricultural buildings to multi-layer systems for industrial and leisure application.

Steel profile sheets are metal structural members that due to the fact they can have different profiles, with different heights and different thickness, engineers and architects can use them for a huge variety of buildings, from a simple industrial building to a high demand design building. Trapezoidal profiles are large metal structural members, which, thanks to the profiling and its thickness, retain their high load bearing capability. They have been developed from the corrugated profile.

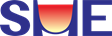

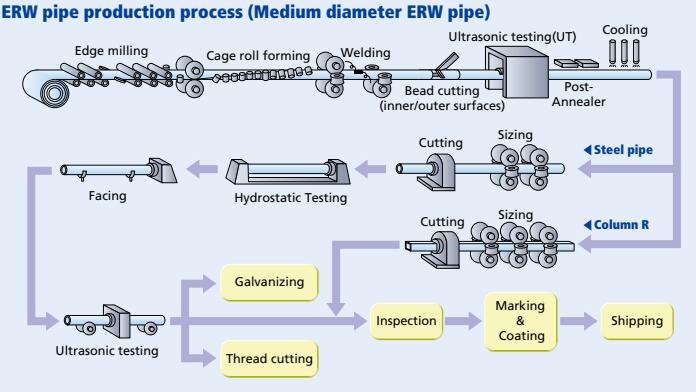

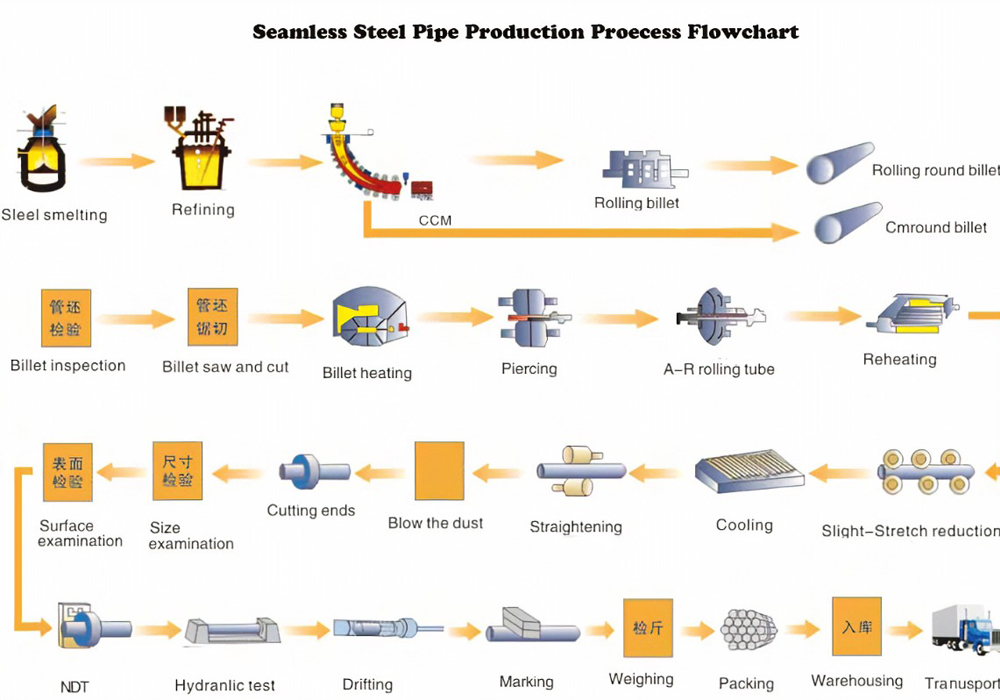

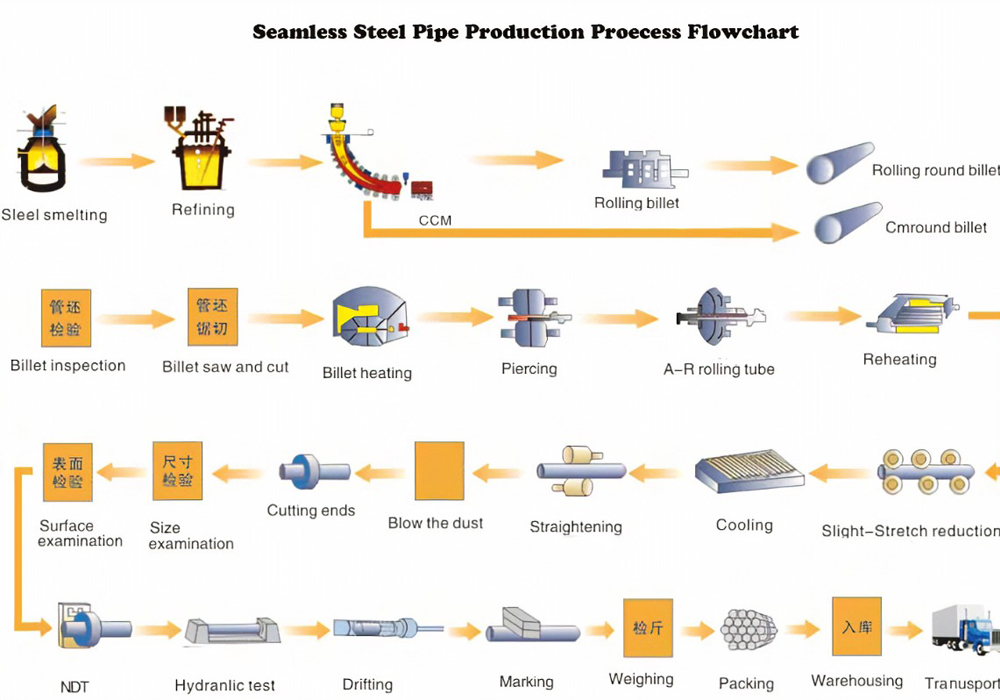

Steel tubes are structural steels of special shapes, including high-frequency welded tubes and seamless tubes

Steel pipe is a hollow section, its length is much larger than the diameter or circumference of steel. According to the sectional shape, it can be divided into round, square, rectangular and special-shaped steel tubes; According to the material is divided into carbon structural steel pipe, low alloy structural steel pipe, alloy steel pipe and composite steel pipe; According to the purpose, it can be divided into conveying pipeline, engineering structure, thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high pressure equipment and so on. According to the production process is divided into seamless steel pipe and welded steel pipe, which is divided into hot rolled and cold rolled (pull) two kinds of seamless steel pipe, welded steel pipe and straight seam welded steel pipe and spiral seam welded steel pipe.

Steel pipe is not only used to transport fluids and powdery solids, exchange heat, manufacture mechanical parts and containers, it is also an economical steel. It can reduce the weight, save 20 ~ 40% of the metal, and realize the industrial mechanized construction. Using steel pipe to manufacture highway bridge can not only save steel, simplify construction, but also greatly reduce the area of protective coating and save investment and maintenance cost.

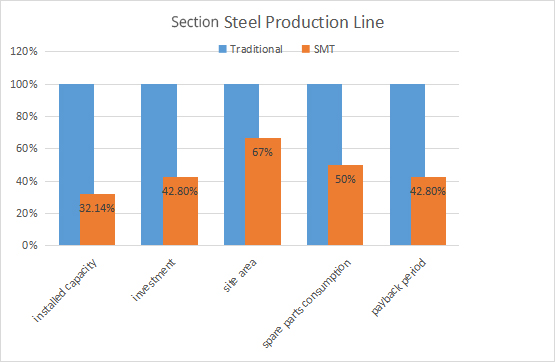

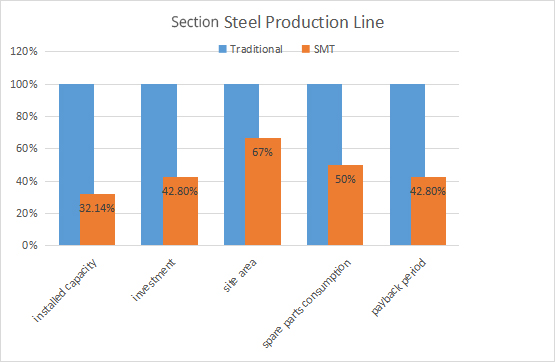

SME has designed various specifications of section steel production lines for customers, including single specifications and multiple specifications, such as I-beam, angle steel, channel steel, T-shaped steel, etc. The traditional rolling production line technology is very mature, and we have a full set of technology and experience. on the basis of traditional process, SME applies the self-developed Pre-Slitting rolling patented technology to the section steel production line. Higher billeting efficiency liberates the design capacity of the rolling mill, the unique roll design reduces the consumption of spare parts, and the configuration of the finishing mill is more flexible and specific.

Compared with the traditional section steel production line of the same capacity, it effectively reduces the direct investment of the production line. The production capacity design of different specifications is more flexible, and the production line consumes less energy. Small-scale production lines can even run directly through generators, with higher production efficiency, lower operation and maintenance costs, and unparalleled market advantages.

With our Pre-Slitting technology, we support our customers in achieving prime quality levels without compromises.

Investment comparison between SME with traditional bar production line as follow

Remarks: The comparative data is based on the same production capacity