Metallurgical Processes And Technologies

Filling wisdom and passion into the evolution of metal

Professional technical background and continuous research and development capabilities ensure that we have the strength to carry forward the past and the future. The accumulated project experience makes us familiar with this. We understand the most primitive state of metal, and we will put our heart into it and finally make it a part of human civilization.

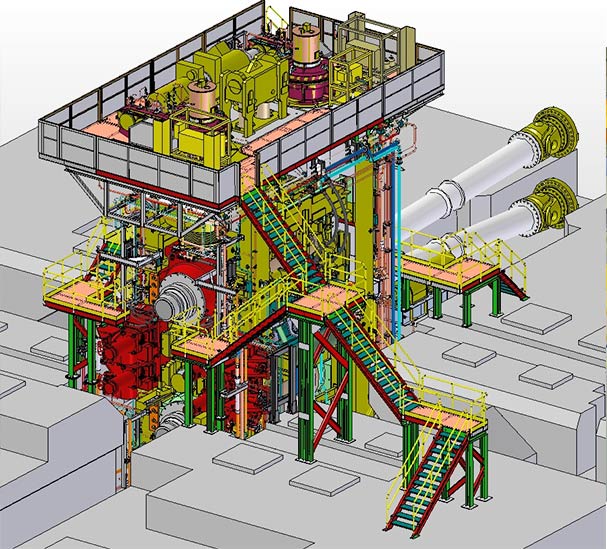

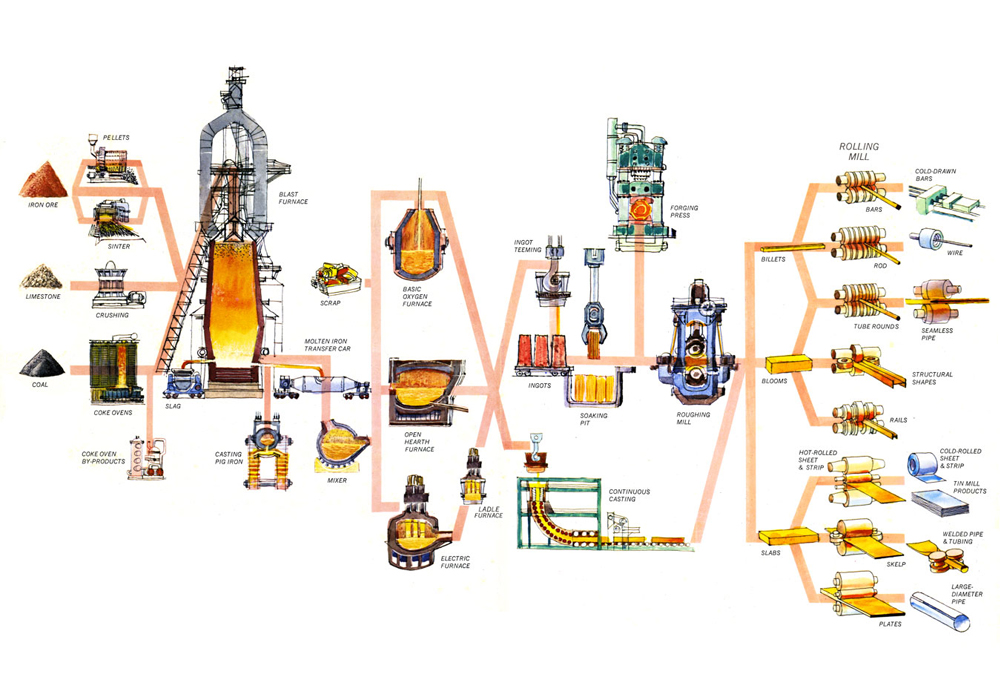

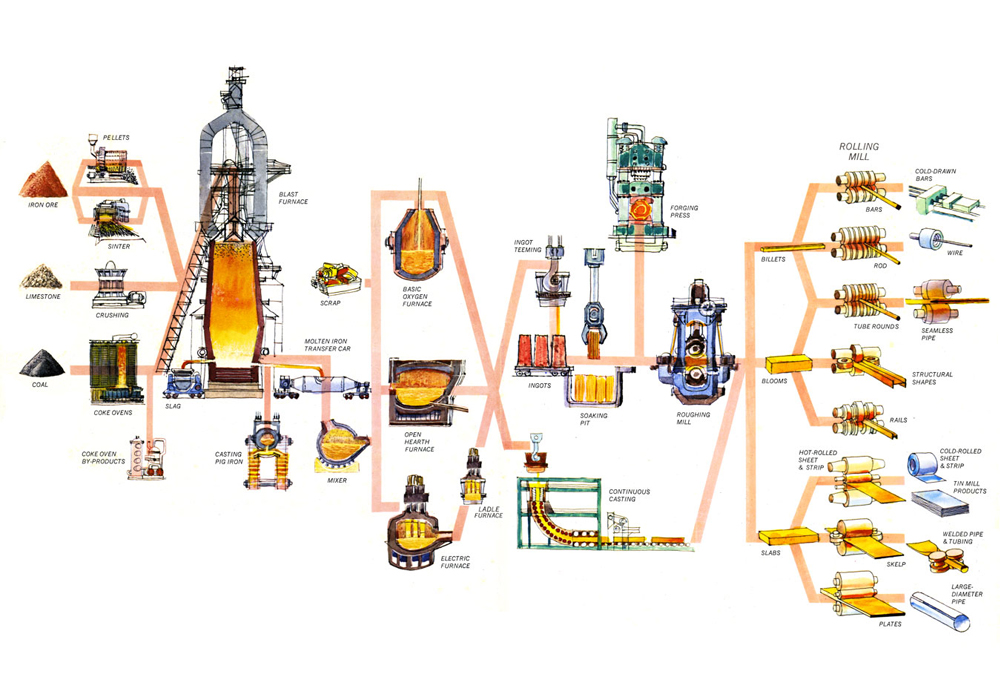

Iron and steel production process mainly includes iron making, steel making, steel rolling and other processes, briefly explained as follows:

(1) Iron making: it is the process of reducing iron from sinter and block ore. Coke, sinter and ore, along with a small amount of limestone, are fed into a blast furnace to produce liquid pig iron (molten iron), which is then sent to a steel mill for use in steelmaking.

(2) Steel making: it is to remove the excessive carbon, sulfur, phosphorus and other impurities in the raw material (hot iron and scrap steel, etc.) and add this amount of alloy composition.

(3) Continuous casting: there is the water by the middle tank into a condenser, which is then condensed into billets. There is then a steady flow of steel out of the crystallizer, and then there is the water spray, and then after solidification, there is the continuous casting billet of a certain length. By radio.

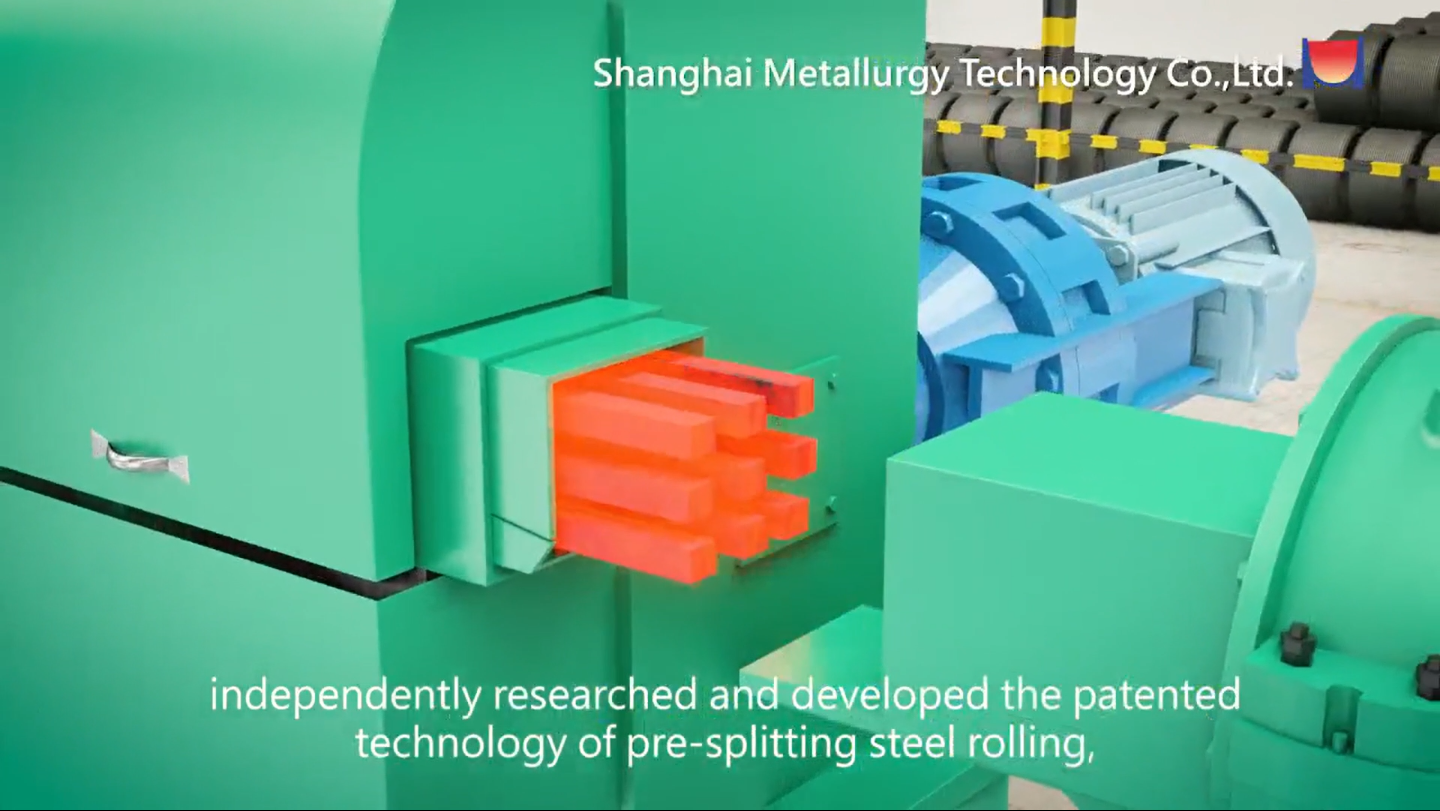

(4) Steel rolling: the ingot and billet produced by continuous casting are rolled into all kinds of steel by hot rolling in different rolling mills.

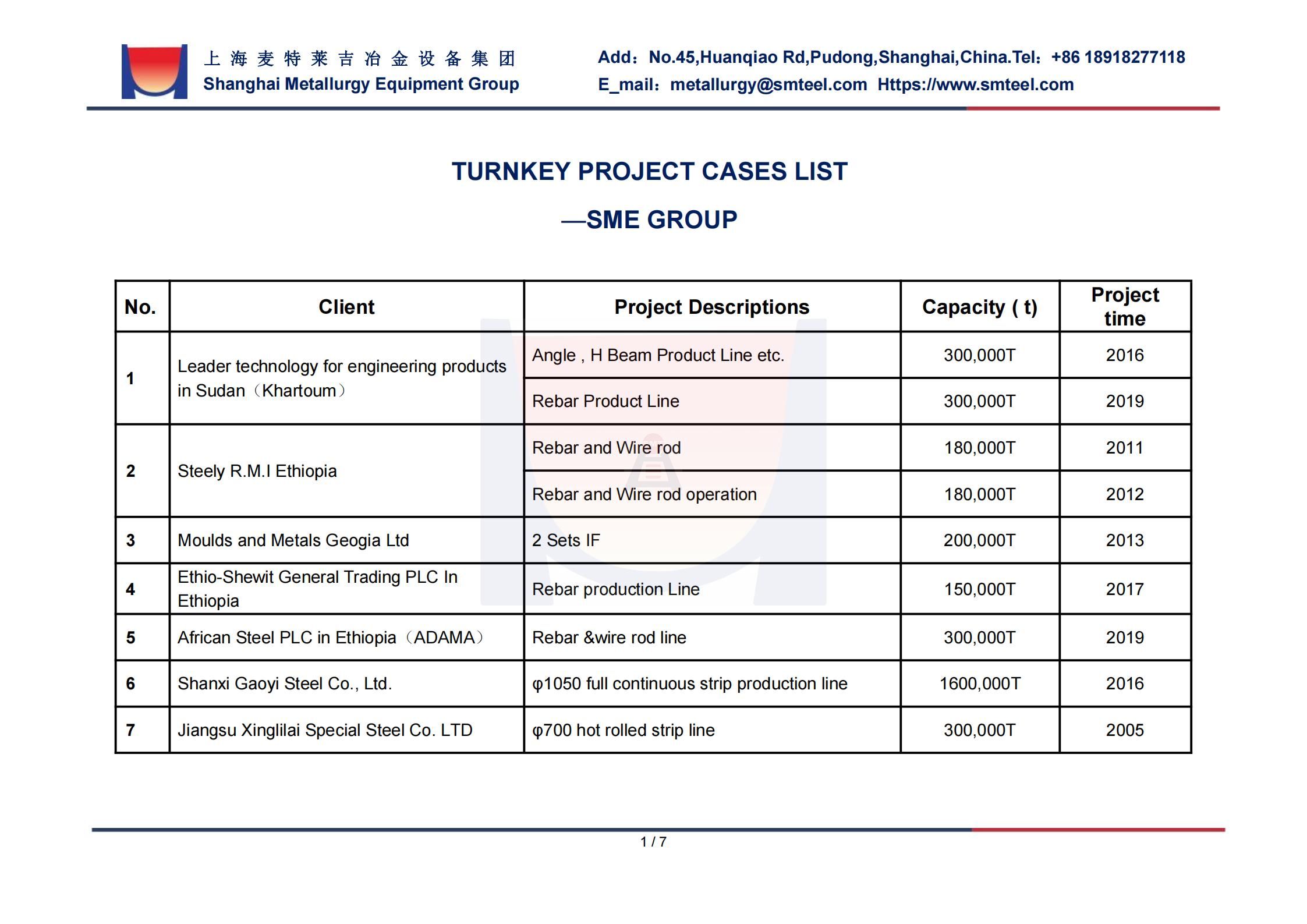

Shanghai Metallurgy Equipment Group masters full set of metallurgical processes, including iron making, steelmaking or steel rolling, or metallurgical engineering and related auxiliary projects, SME Group has enough technology and capital to deliver satisfactory results to customers.

The various metallurgical technologies that SME Group has mastered are very comprehensive and mature, not only because of the technical foundation of metallurgical predecessors, but also because we never stop the pace to a higher level standing on the shoulders of metallurgical predecessors. Our value comes from more advanced metallurgical processes and technologies, in order to provide better service,SME Group continues to innovate traditional processes, equipment, technology and project concepts. The innovation of SME Group is continuous, which is a weapon and barrier to ensure our customers have strong market competitiveness for a long time.