Ironmaking process

Smelting iron ore

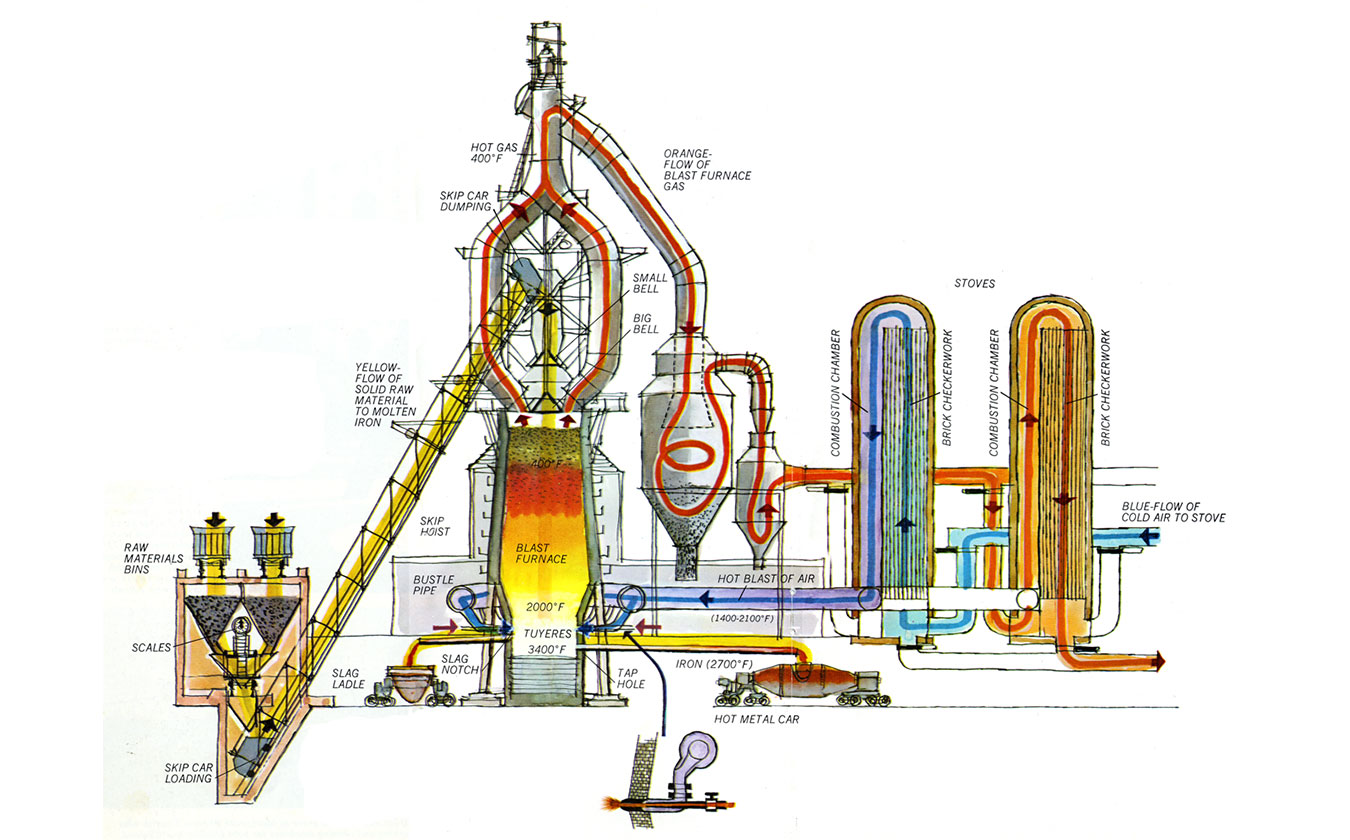

As the upstream industry of the iron and steel production, ironmaking provides, by smelting iron ore and extracting sponge iron, a steady stream of metal for downstream processing field with high quality materials, mainly to the blast furnace smelting and direct reduction ironmaking in the form of two kinds of the blast furnace is used steel plate as a furnace shell, shell build by laying bricks or stones firebrick lining. The body of blast furnace is divided into throat, body, waist, belly and hearth from top to bottom. Because the blast furnace ironmaking technical and economic indicators are good, simple process, large production, high labor production efficiency, low energy consumption advantages, so this method of production of iron accounted for the world's total iron output.

High quality iron ore is the best raw material for blast furnace ironmaking, which will greatly improve the utilization coefficient of blast furnace and optimize the production capacity of blast furnace.

The raw materials used in blast furnace smelting are mainly composed of iron ore, fuel (coke) and flux (limestone).

Generally, smelting 1 ton of pig iron requires 1.5-2.0 tons of iron ore, 0.4-0.6 tons of coke, 0.2-0.4 tons of flux, a total of 2-3 tons of raw materials. In order to ensure the continuity of blast furnace production, it is required to have sufficient quantity of raw material supply.

During blast furnace production, iron ore, coke and slag flux (limestone) are loaded from the top of the furnace, and the preheated air is blown into the tuyere along the bottom of the furnace. In high temperature coke (some blast furnaces also spray pulverized coal, heavy oil, natural gas and other auxiliary fuels) in the carbon with the oxygen in the air combustion generated carbon monoxide and hydrogen, in the furnace rise process to remove the oxygen in iron ore, so as to reduce the iron. The molten iron is released from the iron hole. Unreduced impurities in iron ore combine with fluxes such as limestone to form slag, which is discharged from the slag mouth. The generated gas is discharged from the top of the furnace and used as fuel for hot blast stoves, heating stoves, coke ovens and boilers after dust removal. The main product of blast furnace smelting is pig iron, as well as the by-product of blast furnace slag and blast furnace gas

Shanghai Metallurgy Technology Co., Ltd. has successfully completed more than 110 international metallurgical projects, mastering full set of technologies for advanced small-medium, and MINI blast furnaces, covering effective volumes from 2000m3 to 20 m3, especially the latest developed modular blast furnace, the height is less than 8.5 meters, modular manufacturing and installation let the project construction period shorten within 60 days, and reducing the investment cost by 40%. The payback period of investment is shortened to less than one year. As upstream metallurgical industries, Blast furnace Iron making plant consistently produces high-quality billets and provides to these downstream steel plants as raw material, there will be huge investment value.

SMT insist on creating value for customers with...

Apr. 16 , 2021

We adhere to the people-oriented development conc...

Apr. 06 , 2021Shanghai Metallurgy Technology Co., Ltd.

E-mail: Metallurgy@smteel.com

Skype: +86 189 1827 7118

Tel.: +86 189 1827 7118

Add.: Kangqiao, Pudong new district, Shanghai, China.