BLAST FURNACE IRON MAKING

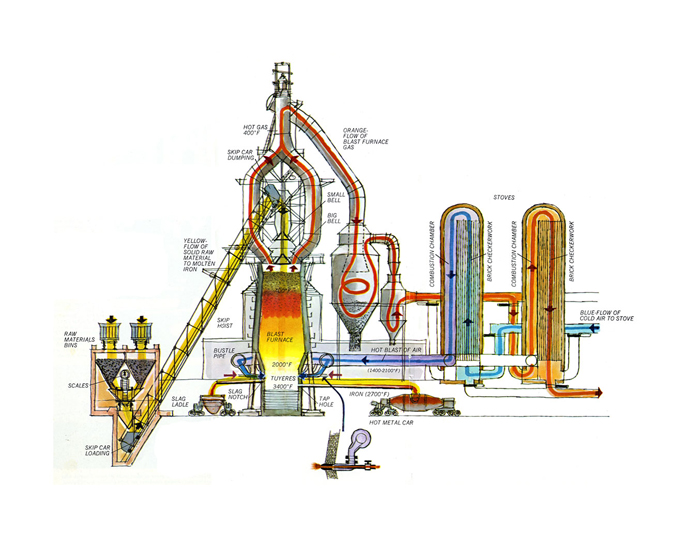

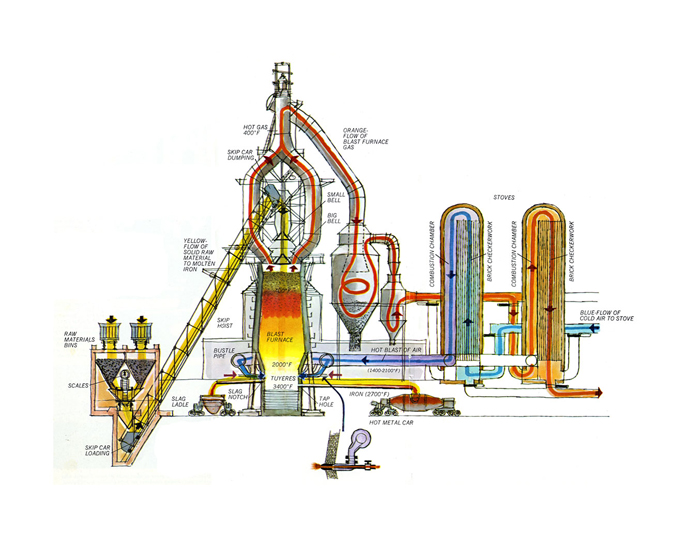

1.What equipments are included in the blast furnace ironmaking system ?

A:The blast furnace ironmaking system mainly includes the blast furnace body, feeding system, hot air system, injection equipment, dust removal system, gas treatment equipment, collection and transportation equipment for molten iron and slag iron, and maybe equipped with sintering machine and cast iron machine according to the actual raw materials and products.

2.What raw materials are needed for blast furnace ironmaking ?

A:Iron ore (sinter ore, pellets, iron powder, etc.), fuel ( Coke) and flux (limestone). Generally, smelting 1 ton of pig iron requires 1.5-2.0 tons of iron ore, 0.4-0.6 tons of coke, 0.2-0.4 tons of flux, and 2-3 tons of raw materials in total. In order to ensure the continuity of blast furnace production, a sufficient amount of raw material supply is required.

3.What are the factors that affect blast furnace productivity ?

A:Iron-making workers at home and abroad have recognized that blast-furnace iron-making is based on concentrate. The impact rate of refining technology on blast furnace production indicators is 70%, the impact of the foreman's operation level is 10%, the modern management level of the enterprise is 10%, the equipment operation level is 5%, and external factors (power, supply, upper and lower processes, etc.) 5%. Under the condition of high smelting intensity and high coal injection ratio, the influence rate of coke quality change on blast furnace index is about 35%.

It is hoped that the ore grade of the blast furnace should be ≥58%, the charge contains low SiO2, low Al2O3, and low MgO, the blast furnace slag ratio is below 300kg/t iron, the M10 of coke is less than 7%, and the reactivity (CRI) is less than or equal to 25%. , the strength after the reaction is ≥65%, etc., which is a necessary condition to ensure high efficiency, low consumption and large coal injection in blast furnace production.

4.How to calculate the approximate capacity of a blast furnace?

A:The production capacity blast furnace is generally given by year, the effective utilization coefficient of the blast furnace is generally 2.0-3.0 t/(m³.d), for example, a 50m³ blast furnace is calculated according to the utilization coefficient of 3.0, producing 150 tons of iron per day, The annual production capacity is about 150*300=45,000 tons of iron (excluding the maintenance time of blast furnace), so the annual production capacity of the 50m³ blast furnace is about 50,000 tons of iron per year.

5.Can natural gas and coal be used instead of coke as fuel for blast furnaces?

A:Let us first clarify the role of coke, one is to burn to supply heat (heat source); the other is to serve as a material column skeleton (air window); the third is to act as a reducing agent; the fourth is to supply carbon

①: Material Column skeleton: The coke bulk density in the blast furnace charge is the smallest, the gap is large, and the volume accounts for 35%-50% of the total volume of the charge. The coke is relatively strong, and it always remains lumpy as long as it is above the tuyere area, which can make the material column have good gas permeability and keep the furnace condition stable.

②: Reducing agent: the carbon content of the coke is more than 85%, the high temperature carbon dioxide gas reacts with the carbon in the coke to generate carbon monoxide, and the carbon monoxide further reduces the iron ore to generate molten iron.

③: Carbon supply: The carbon content of pig iron is about 4%, all of which come from blast furnace coke, accounting for 7%-9% of the carbon content of coke.

④: Heat supply: coke coke, the combustion of fuel injection and the hot air introduced from the outside provide all the heat required for blast furnace smelting, of which the proportion of coke combustion heat supply is as high as 75%-80%.

The reaction in the blast furnace occurs between "one liter and one drop", that is, the rise of the gas and the fall of the charge, which requires the charge column to have good gas permeability, so that the iron ore can be fully reduced. Coal is not as good as coke, and after being crushed, it will cause a decrease in the permeability of the blast furnace. Enterprises may appropriately increase the proportion of pulverized coal injection to reduce production costs, but coke must be used in the reduction reaction and skeleton action, which cannot be replaced at present.