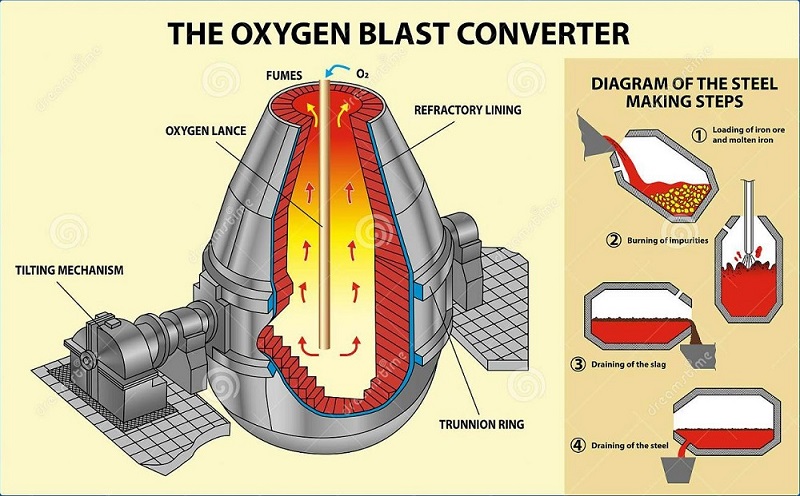

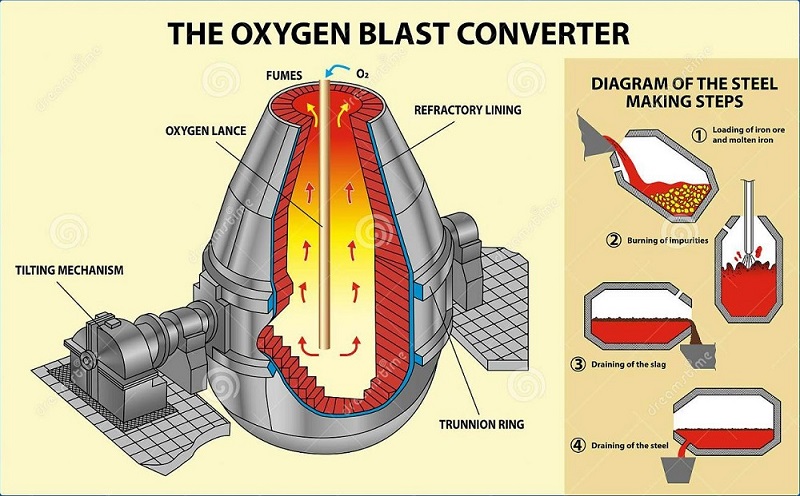

Basic Oxygen Steelmaking

Converter Steelmaking-From Molten Iron

1.Basic Principle

BOF(converter) steelmaking is based on molten iron, scrap steel and ferroalloy as the main raw materials, without the aid of external energy, relying on the physical heat of liquid iron itself and the chemical reaction between liquid iron components to produce heat and complete the steelmaking process in the BOF. The converter is divided into acid and alkaline according to the refractory material, according to the parts of the gas blowing into the furnace with top blowing, bottom blowing and side blowing; According to the type of gas for air converter and oxygen converter. The bof is the most commonly used steelmaking equipment because of its fast production speed, large output, high output of single furnace, low cost and less investment. The converter is mainly used for the production of carbon steel, alloy steel and copper and nickel smelting.

2.Emergence And Development

As early as 1856, The British Bessemer invented the bottom blown acid converter steelmaking method, which was the beginning of modern steelmaking. It produced a large number of cheap steel for human beings and promoted the Industrial revolution in Europe. But its development has been limited by its inability to remove sulfur and phosphorus. Pure oxygen top-blown converter in Austria in 1952 appeared, it solves the content of nitrogen in steel and other harmful impurities, make quality close to the open hearth furnace steel, at the same time reduces along with the exhaust (when using ordinary air blowing, the air containing 79% useless nitrogen) loss of heat, can open hearth furnace pig iron melting temperature is low, thus saving the coke consumption of blast furnace, And use more scrap steel. Due to the fast speed of bof steelmaking (about 10min for a furnace of steel, and 7h for open hearth furnace), negative energy steelmaking, energy saving, so bof steelmaking has become the mainstream of contemporary steelmaking.

3.Raw Material

BOF(converter) steelmaking raw materials are divided into metal materials, non-metal materials and gas. Metal materials include molten iron, scrap steel, ferroalloy, non-metallic materials include slag, flux, coolant, and gases include oxygen, nitrogen, argon, carbon dioxide, etc. Nonmetallic materials are added in order to remove impurities such as phosphorus and sulfur and control the temperature in the process of converter steelmaking. Mainly slag (lime, dolomite), flux (fluorite, iron oxide), coolant (iron ore, limestone, scrap steel), carburizer and fuel (coke, graphite seed, coal, heavy oil).

4.Satisfiable Product Range

Mild steel is the main product of converter steelmaking. Because of the fast decarburization of the converter and the low gas content of the steel, the plasticity and low temperature plasticity of the steel are good, and the steel has good deep drawing and welding performance. Bof steel is used to manufacture hot rolled sheet, cold rolled sheet, galvanized sheet, automobile sheet, cold formed steel, low carbon soft steel wire, etc., all have good performance.

Although there are some difficulties in smelting medium and high carbon steel with converter, the quality of steel can be guaranteed. All kinds of structural steel, bearing steel and hard steel wire manufactured by converter steel have been widely used.

Converter smelting low alloy steel has no special difficulty.

It is difficult to smelt ultra-low carbon steel (C<0.03%) with BOF(converter).

Main technical and economic indicators Take 150-300T converter as an example, the main technical and economic indicators are as follows:

Smelting cycle

| 30min |

| Thereinto: oxygen blowing time | 16~20min |

Oxygen consumption | 48~58m3/t |

Iron and steel consumption | 1060~1150kg/t |

Steel Scrap | 15% ~ 30% |

Limestone consumption (including dolomite) | 30-70kg/t |

| Fluorite consumption | 0.0 ~ 3.0 kg/t |

| Iron ore consumption | 30~50kg/t |

Furnace lining refractory consumption | 3~7kg/t |

| Power consumption | 9 ~ 12 kw · h/t |

| Annual output (nominal tonnage) | 10000 ~ 15000 |