Remark: SME owns all intellectual property rights, infringement must be investigated

CHOOSE US?

100+ Project Cases

20+ Years of Turnkey Project Experience

Help you save investment cost up to 50%

REBAR/WIRE ROD PRODUCTION LINE

SME applies the self-developed slitting rolling patented technology to steel bar, rebar and wire rod rolling process. Its' efficient slitting capacity will give full play to the productivity of rolling mill. Modular equipments and offline straightening production methods make the plant location seclection and implementation more flexible. Smaller installed capacity enables even small scale steel rolling line to be run directly by generators. And that the cost of spare parts and maintenance will be greatly reduced, investors will have higher profit margin.

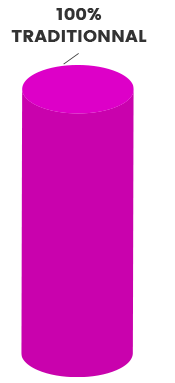

SME steel has been striving to reduce the investment cost of steel bar and wire rod production lines. tmt steel bar and wire rod has a wide range of uses, whether in construction or daily life. The latest equipment and processes independently developed by SME have effectively reduced equipment investment costs and project cycles, especially for small-capacity wire rods. The investment economy of production lines, traditional processes and equipment is poor, and the designed capacity is largely wasted. The investment cost is truly linked to the production capacity to protect the long-term interests of investors.

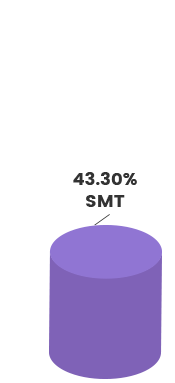

| installed capacity | investment | site area | spare parts consumption | payback period | |

| Traditional | 100% | 100% | 100% | 100% | 100% |

| SME | 25.50% | 43.30% | 52% | 60% | 43.30% |

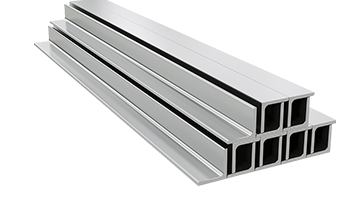

STRUCTURAL STEEL PRODUCTION LINE

SECTION STEEL & STEEL PIPE

New profile steel rolling process adopts the slitting rolling technology, in addition to greatly reducing the unit investment of steel project, whose product specifications and capacity design are more flexible including angle steel, H steel, U steel, etc., modular design enables the installation to be completed within 60 days. Compared with the traditional, it has lower requirements for location selection and electricity, lower production consumption and maintenance costs. Producing all series of section steel with stronger market competitiveness.

SME steel has designed a variety of section steel and steel pipe production lines for different investors, including angle steel, channel steel, I-beam, seamless pipe, welded pipe, etc. These projects have been successfully implemented. Mature process technology and high-performance production equipment are the basis for us to protect the interests of investors. The most important thing is that our experts and R&D team always strive to reduce investment costs, which is our value.

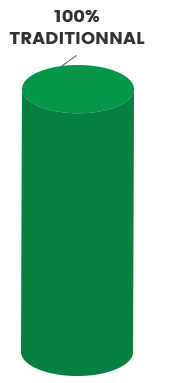

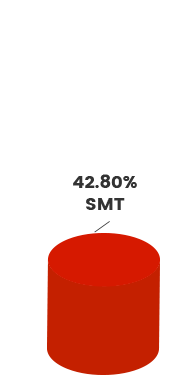

| installed capacity | investment | site area | spare parts consumption | payback period | |

| Traditional | 100% | 100% | 100% | 100% | 100% |

| SME | 32.14% | 42.80% | 67% | 50% | 42.80% |

STEEL STRIP & TUBE PRODUCTION LINE

SME's steel strip & tube rolling process adopts self-developed slitting rolling technology, rotate steel distribution technology, and multi-line rolling technology etc., which directly lead to a decrease in installed capacity and equipment investment cost. Flexible modular design of pre-slitting strip steel rolling production line will reduce various costs in all directions, and greatly shortens the project installation cycle, which enable investors to have shorter payback period.

SME steel masters the mature process technology of hot-rolled strip and cold-rolled coil. According to the customer's product use, SME's professional team designs the production process and provides comprehensive solutions, including investment economy, equipment selection, capacity design , Strip steel products have higher added value and a large number of downstream market demands. The technical solutions provided by SME are market-oriented and leave enough space for future production line upgrades to give full play to customer value orientation.

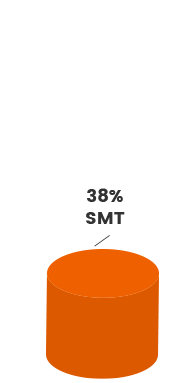

| Installed capacity | Investment | Site area | Spare parts consumption | Payback period | |

| Traditional | 100% | 100% | 100% | 100% | 100% |

| SME | 14.2% | 38% | 65% | 55% | 38% |